As published in Manufacturing & Construction News - March 1, 2020

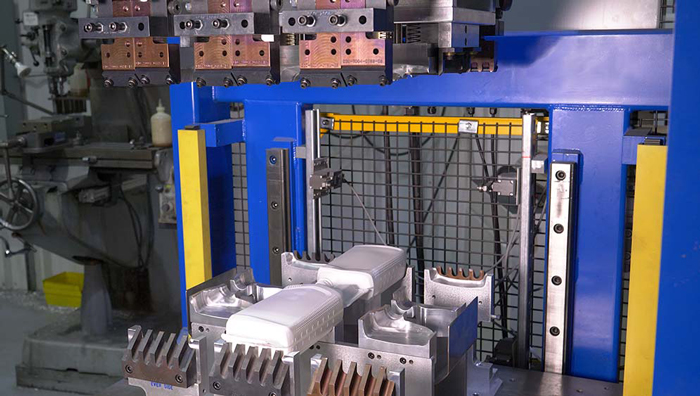

Century Die designs and builds downstream tooling and machines

Century Die adds new machining center

New automation expected to help company run more efficiently

Century Die, a machine shop and blow-molding fabricator located in Fremont, Ohio that uses state-of-the-art CNC machines, lathes, and milling machines to produce tooling in the blow mold process, has added a new 5-axis machining center with automation.

According to Tim Myers, general manager, Century Die, the new equipment will help the plant run more efficiently with its current manpower and allows the company to bring in more diverse work.

“We need to be efficient and keep costs down. With automation, it helps us to accomplish that. We have rising costs and labor rates continue to rise as well. It’s hard to find labor so it costs more money, and on top of that, healthcare is ridiculously out of control and a high cost for us. Materials and whatnot have also increased in price and that’s really bad for us. In order to hold pricing for our customers and be competitive, automation is the step we are making into the machining world,” said Myers.

According to Myers, it took five months to get the equipment from Germany up and running at the plant, and the company began production in late December. The company has two buildings on its campus totaling between 30,000-35,000 square feet.

Myers noted that Century Die is known for producing the new tooling for the consumer packaging industry – including mold tubing, plastic bottles, and packaging – but the company also produces molds, trimmer tooling, and secondary machines for automotive, appliance, industrial, and recreation industries, as well as performing contract machining.

Century Die has four grinding machines, which include two-Kents, one-Blohm-Korber, and one-Blohm-Simplex with the largest able to grind 24W” x 60L” x 14H”

“Century has been delivering superior molds along with downstream tooling to industry leaders for more than 70 years,” said Myers.

In total, the company’s services include ancillary mold devices, blow molds, custom machining, engineering, inspection, and mold repair and refurbishing. Myers noted that the company’s expertise includes EDM, finishing, grinding, milling, turning, water jet, and welding.

The company has 70 employees at its Fremont operations, but according to Myers, the capital machinery expansion will not directly add jobs.

“Indirectly, the capital machinery expansion will bring jobs because it gives us the opportunity to expand our capacity to diversify into other areas and bring in more work,” explained Myers. “We want to be a leader in technology and tooling, and along with that, our customer service, I think that sets us apart and will help us into the future.”